Mangla is one of the lead manufacturers and exporters of Paper Mill Plants Machinery parts like M.G. Dryer, Rotary Spherical Digester, continuous Digest, Pul and Popeeler.

We started manufacturing Paper Mill Machinery Parts in the early eighties under the banner of our sister concern i.e. M/S. Asha Steel Industries and have delivered the best quality products all over India and outside India. We have the complete facility of testing and machining of these equipments.

- M.G. Dryer

- Dryer Section

- Rotary Spherical Digester

- Continuous Digester

- Pulper

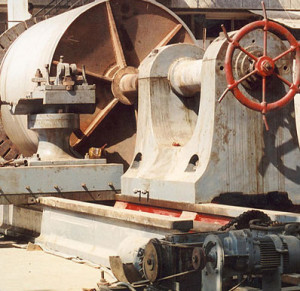

M.G DRYER :

- M.S. Fabricated M.G Dryers up to 6 ft. Dia. and width up to 3.5 m available

- Shell Plate thickness rolled up to 80 mm having ovality within 2-3 mm before machining and grinding

- Heavy duty framing for vibration free movement

- Hydraulic Pressure testing at 10 kg/cm2

- Material used for fabrication is IS2002 or IS2062 Gr. B

- All shell plate welding joints are X-Ray tested

- S.R facility to remove stresses during bending and welding

- Bucket scooping system to remove condensate

DRYER SECTION :

- M.S. Fabricated Dryers available upto 6 ft. Diameter and 3.5 m width

- Shell thickness varies from 25 to 36 mm

- Heavy duty framing both in M.S and C.I. available

- Pressure testing up to 10 Kg/cm2

- Perfect round before machining so as to get even cut during machining results in uniform evaporation.

- Rope feeding arrangement is also provided as per client requirement

- Dynamic Balancing

- Gear both in M.S. and C.I. available

ROTARY SPHERICAL DIGESTER :

- Spherical Digester are available up to 16 ft. Diameter.

- Plate thickness basics from 20 to 25 mm.

- Material of plates used IS 2062 or IS 2002

- Bucket scooping system to remove condensate.

- All welding joints are Ultrasonic tested.

- Inside backing strips provided to strengthen the joints.

CONTINUOUS DIGESTER :

Continuous Digester System is used in order to obtain consistent and better quality of pulp, low steam consumption and cooking time, reduce labour and production cost and provides flexibility of operations to use various raw materials. In this system, we manufacture various equipments like Digester Tube with screw (both M.S and S.S), Cold Blow Discharger and Inlet Chamber.

PULPER :

SALIENT FEATURES:

- Pulper available up to 16 m capacity

- Reduced pulping time

- Bearing mounted, Pulley and Belt driven

- Low residual flake contents

- Low residual stickies contents

| List of Paper Plant Customers | ||

| CLIENT NAME | LOCATION | EQUIPMENT SUPPLIED |

| Galaxy Papers Pvt. Ltd. | Muzaffarnagar, (U.P) | Dryers |

| Ever shine Papers Pvt. Ltd. | Ludhiana, Punjab | Dryers |

| Karnal Paper Board Mills Pvt. Ltd. | Karnal, Haryana | M.G., Dryers |

| Goraya Paper Mills Pvt. Ltd. | Kashipur, Uttaranchal | Digestors |

| Gahir Paper Mills Pvt. Ltd. | Sunam, Punjab | Dryers |

| Baba Paper Mills Pvt. Ltd. | Nepal | Digestors |

| Umesh Board & Paper Mills Pvt. Ltd. | Aurangabad, Maharashtra | M.G Dryers |

| Agro Pulping Machinery Pvt. Ltd. | Chennai | Digester Tubes |

| Sideshwari Papers Ltd. | Kashipur | Surface Condensor |